Biomass-to-Liquids (BtL) - The bioliq® Process

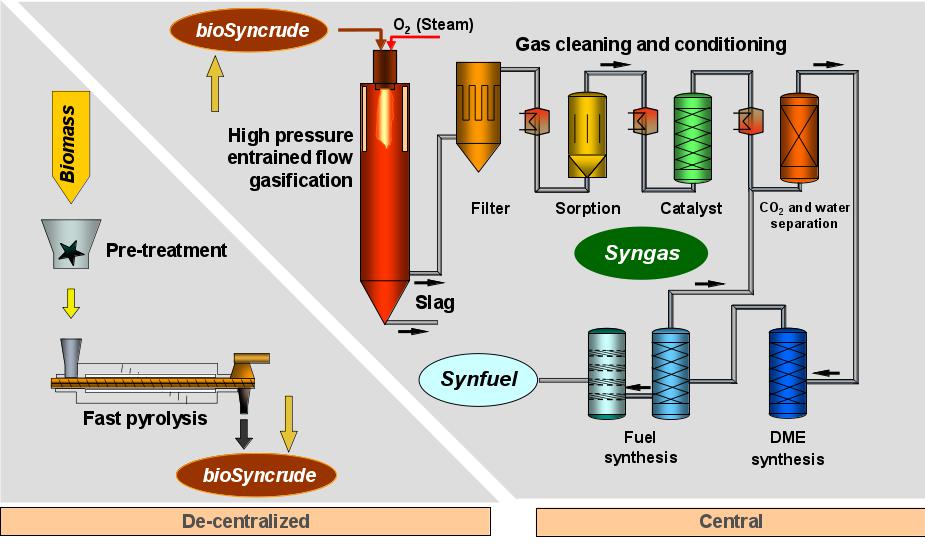

The bioliq® pilot plant covers the complete process chain required for producing customized fuels from residual biomass. For energy densification of the biomass, fast pyrolysis is applied. The liquid pyrolysis oil and solid char obtained can be processed into intermediate fuels of high energy density. Fuel and chemicals production from syngas requires high pressures. Therefore, syngas production is already performed at pressures up to 80 bar by entrained flow gasification. Gas cleaning and conditioning are conducted at the same pressure at high temperatures allowing for optimal heat recovery and thus improved energy efficiency. In the bioliq® pilot plant the purified syngas is firstly converted into dimethyl ether and then further to gasoline.

Fig. 1: Process flow chart bioliq® process

© KIT 2025