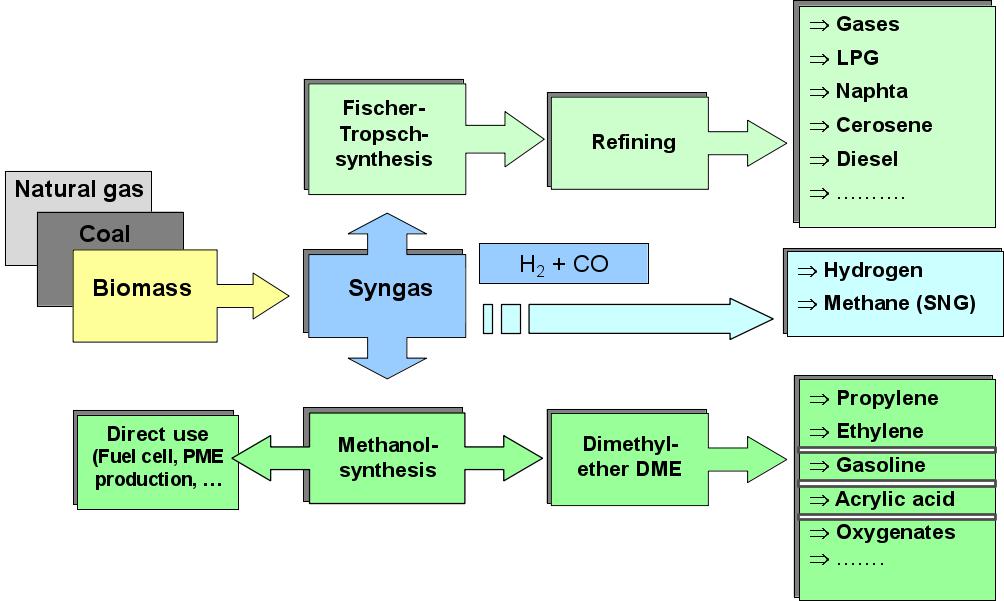

Fuels produced from syngas principally are state of the art today, when coal or natural gas are used as feedstock resource. By the so-called CtL (coal to liquids) and GtL (gas to liquids) processes fuels and chemicals are produced in large scale industrial plants e.g. in South Africa, Qatar, or China. Also, methanol and dimethyl ether production are established processes. On a longer term, KIT aims at the development of high performance fuels or fuel components, leading to improved combustion properties and emissions in existing engines as well as at the development of new fuels tailor made for new combustion concepts like e.g. the gasoline direct injection.

The bioliq® pilot plant is designed for gasoline production via an innovative dimethyl ether synthesis as intermediate step. However, from syngas many chemical pathways are possible to produce gaseous and liquid fuels and chemicals.

Advantages of BTL Fuels over Conventional Fuels

- Reduction of carbon dioxide emissions.

- Saving of fossil fuels.

- Independence of energy imports to some extent.

- Strengthening of regional agriculture.

- Wide range of raw materials.

- No competition for land with food production.

- Infrastructures: Filling stations and routes of distribution can continue to be used.

- Fuels (“designer fuels“) can be tailored to the needs of different types of engines.

- Covering of a large variety of fuel types.

Fig. 1: Product path

© KIT 2022