The biosyncrude is atomized with hot oxygen in an entrained-flow gasifier and is converted at above 1200 °C into a tar-free, low-methane raw synthesis gas. The gasifier used is particularly suited for the high amounts of biomass ashes that are produced during gasification. The process is performed at pressures that are determined by the subsequent synthesis. There is no need for complex gas compression procedures. While Fischer-Tropsch syntheses require process pressures of up to 30 bar, methanol or dimethyl ether (DME) syntheses are carried out at up to 80 bar. The bioliq® pilot gasifier is designed for 5 MW (1t/h) and two pressure stages of 40 and 80 bar.

High Pressure Entrained Flow Gasification: Institute for Technical Chemistry (ITC)

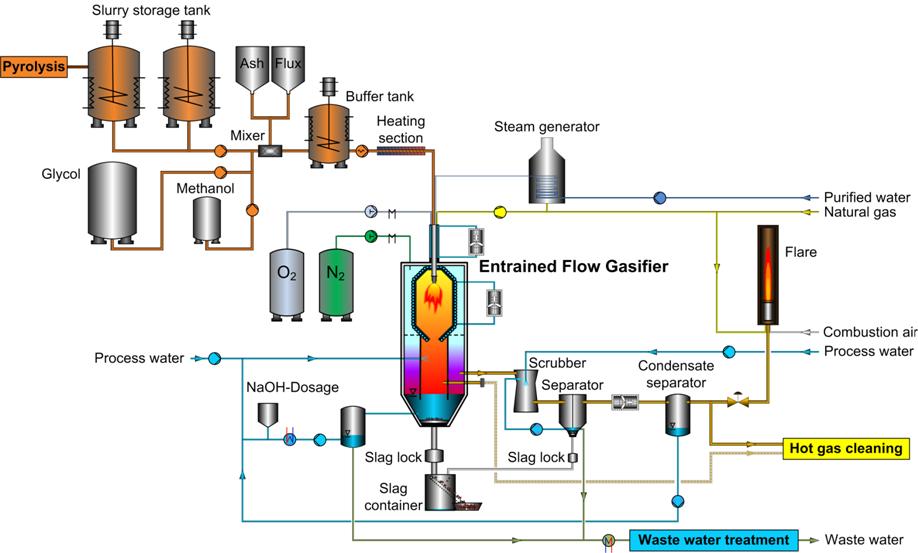

Fig. 1: Flow process chart of the gasification

© KIT 2022